Structural material design - power saving, fast speed and low malfunction rate.

The worktable of our laminating machine is welded without welding, and it is bonded by high temperature resistant structural adhesive with high strength. Many manufacturers' workbenches are welded, which will cause uneven products.

Technical Parameters:

| Power | 23KW |

| Work table inner size | 1230*2870mm for single working table |

| 1230*2870mm & 1080*2870mm for double working table | |

| Overall dimension | 7000*2100*2000mm for single working table |

| 11000*2100*2000mm for double working table | |

| Vacuum pressure | Max.0.095Mpa |

| Machine weight | 3500kg for double working table |

| 2500kg for single working table |

| Vacuum pump | Domestic first class brand(shanghai zhongde) |

| Electrical Components | Schneider |

| Pneumatic Components | Air TAC Taiwan |

| Heating tube | Chrome nickel wire |

| C ontroller | Mitsubishi |

| Stepping Motor | Yaskawa |

| Pumps capacity | 140M3 |

| Gas tank capacity | 0.85m3 |

Machine advantage:

1. Structural material design - power saving, fast speed and low malfunction rate.

The worktable of our laminating machine is welded without welding, and it is bonded by high temperature resistant structural adhesive with high strength. Many manufacturers' workbenches are welded, which will cause uneven products.

The material of our sealing strip is silicone, which has long life, anti-aging and good sealing performance. At present, most manufacturers use nitrile rubber, which will become hard and dry after long-term use, resulting in poor sealing performance.

Our work surface is wrapped around with silicone, and the edges of the work surface are designed with a slope. The advantages of this are as follows:

Ø PVC film stretch is small

Ø High utilization rate of work surface

ØUsing non-adhesive PVC, no sticky film, good sealing

2. Intelligence

The height and temperature of the heating chamber are intelligently matched according to the thickness of the film. Its not easy to break the film, nor easy to change color

3.Heating tube

The heating tube adopts chrome-nickel wire, which saves electricity, has high speed and long service life. General manufacturers use iron-chromium-aluminum wire for heating, which is relatively expensive. The chrome wire nickel heating tube can save nearly 4 times of electricity.

Our heating pipe installation design is different from other manufacturers. Other manufacturers are currently parallel to the feeding and discharging direction, which will cause a problem that the film-coated sheets on the outermost sides are not uniformly heated.

The design of our machine improves the problem. The heating tube is perpendicular to the incoming and outgoing materials, and the heating of the entire heating chamber is uniform. And it can be heated according to the number of sub-regions of the processed plate, which greatly saves electricity.

Maintenance: The heating tube parallel to the feeding and discharging direction requires workers go into the heating bin for maintenance of the heating tubes, which is extremely inconvenient. Our 3300D can be repaired and replaced on the outside of the machine.

4.Different from other manufacturers, our machine uses high and low pressure. Create an inertia in the form of pulses, suck it and heat it up. Under the low pressure the film is slowly stretched and wrapped around the sheet, so that the side of the sheet will not break the film due to improper pressure. The original color of the film is also maintained. Then the heating chamber is automatically converted into high pressure during the downward movement, and the temperature is radiated vertically to the surface of the film, and the film on the surface is completely adsorbed on the plate.

5. Automatic frame pressing and automatic locking. Save time and labor.

6. Heating compartment heating. After manual setting, the machine can automatically adjust the temperature of the heating chamber. There is a thermal insulation curtain on the machine, which reduces the alternation of cold and heat, ensures uniform temperature, and achieves the effect of power saving.

7. Cold absorption, Heat absorption function.

Cold suction function is to suction in advance on the table outside the machine, check whether the film is fine, and then automatically convert to high pressure suction when entering the Chamber. This is suitable for shallow flat shape, simple door panels, doors, large panels, etc., It is not suitable for cabinet doors.

The heat absorption function is to directly enter the heating chamber for suction. It is suitable for workpieces with deep and complex shapes. Such as Cabinet door.

8. Spray cooling, most manufacturers use fans to cool down and easily raise dust. The spray cooling is faster and healthier.

9.Heating Chamber intelligently move, High and low pressure point vibration technology patent, the first in China

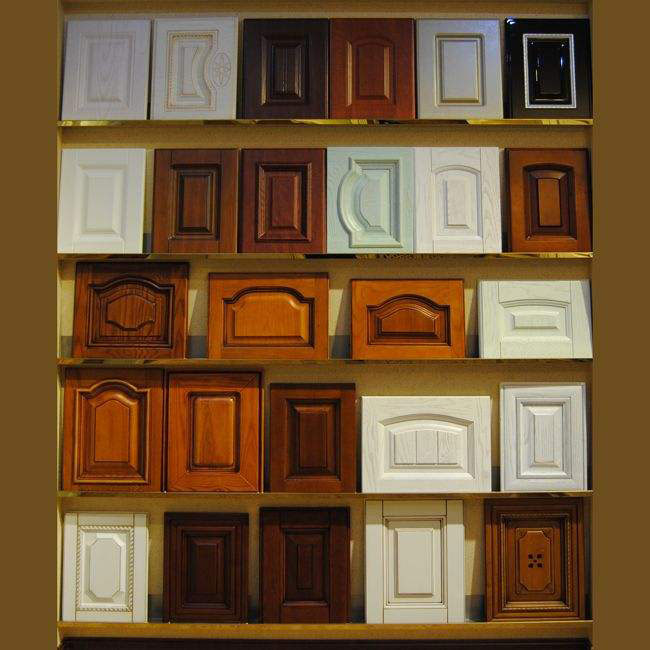

Finished products:

Application: